Affordable Custom-Made Furniture in Singapore - Unique Sofa Designs

Furniture Custom Made: Expert Design and Manufacturing in Singapore

Custom-made furniture offers a unique opportunity to transform your living space with pieces tailored to your exact specifications. In Singapore, a thriving design scene has given rise to expert craftsmen and designers who specialize in creating bespoke furniture. These artisans blend traditional woodworking techniques with modern design sensibilities to produce one-of-a-kind items for every room in the home.

Custom furniture allows homeowners to optimize their space, express their personal style, and invest in high-quality pieces that stand the test of time. From bedframes and sofas to storage solutions, each item is carefully crafted using premium materials like solid wood, ensuring durability and longevity. The manufacturing process involves close collaboration between clients and designers, resulting in furniture that perfectly fits both the physical dimensions and aesthetic vision of a space.

Choosing custom-made furniture opens up a world of possibilities in terms of design, finish, and functionality. Clients can select from a wide range of fabrics types, colors, and styles to create pieces that complement their existing decor or serve as striking focal points. Whether designing a cozy bedroom retreat or a functional settee, custom furniture provides the flexibility to meet specific needs and preferences.

Key Takeaways

- Custom-made furniture offers personalized design and optimal space utilization

- Expert craftsmen in Singapore blend traditional techniques with modern aesthetics

- Bespoke furniture allows for tailored functionality and premium material selection

Understanding Custom-Made Furniture

Custom-made furniture offers unique designs tailored to individual preferences and spaces. It combines skilled craftsmanship with high-quality materials to create personalized pieces that enhance home aesthetics and functionality.

The Craft of Custom Furniture Singapore

Singapore's custom furniture scene thrives on local craftsmanship. Skilled artisans blend traditional techniques with modern design principles. They create pieces that reflect the city-state's multicultural heritage and contemporary style.

Custom furniture makers in Singapore often specialize in specific materials or styles. Some focus on upholstery, while others excel in metalwork or wood. These experts collaborate closely with clients to bring visions to life.

The custom furniture process typically involves several steps. It starts with client consultations and design sketches. Craftsmen then select materials and begin fabrication. The final stages include finishing and installation.

Materials and Quality in Furniture Making

Premium materials are essential in custom furniture production. Fabrics like performance fabrics, cotton, and leather are popular choices. These fabrics offer comfortness and aesthetic appeal.

Quality control is rigorous in custom furniture production. Craftsmen inspect each piece at various stages of creation. They check for structural integrity, finish quality, and adherence to design specifications.

Design Principles and Human-Centric Approach

Custom furniture design focuses on human-centric principles. Designers consider ergonomics, functionality, and personal preferences. They create pieces that fit seamlessly into clients' lifestyles and spaces.

Proportions and scale play crucial roles in custom furniture design. Designers carefully calculate dimensions to ensure pieces fit perfectly in intended spaces. They also consider visual balance and harmony with existing decor.

Customization extends to finishes and details. Clients can choose from a range of colors, textures, and hardware options. This level of personalization results in truly unique pieces that reflect individual tastes.

Foam Selection for Bespoke Pieces

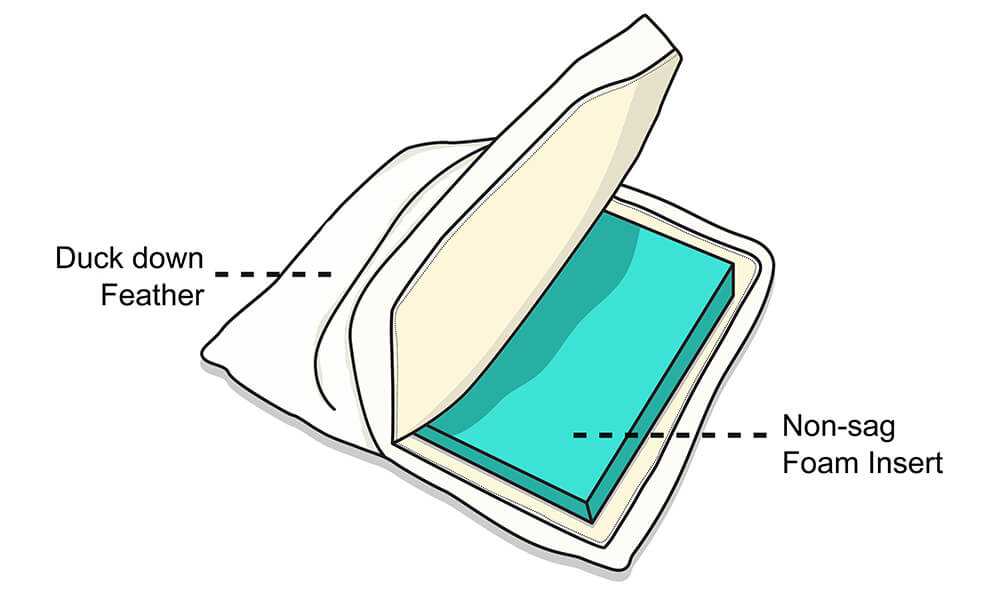

Feather Sandwich™ is a special combination of duck down feather wrapped over a foam core. Danovel has a unique trademarked way of ensuring the best comfort without making the seat too soft. Its interchangeable center foam core allow you to replace it or the feather down mix easily. And of course there isn’t a need to change the foam core as Danovel uses a quality material which is Non-Sag Foam.

Apart from our excellent comfort level, quality down proof material is used to contain the feather ensuring they are kept in their position always, the duck down feathers used in Danovel’s Feather Sandwich™ seat construction comes from responsible sources in Taiwan. Not all feathers are the same, Danovel only uses small feathers with a certain percentage of down to ensure the balance between the soft touch and durability. Large feathers tend to be brittle and less comfortable, with shorter life span

Apart from our excellent comfort level, quality down proof material is used to contain the feather ensuring they are kept in their position always, the duck down feathers used in Danovel’s Feather Sandwich™ seat construction comes from responsible sources in Taiwan. Not all feathers are the same, Danovel only uses small feathers with a certain percentage of down to ensure the balance between the soft touch and durability. Large feathers tend to be brittle and less comfortable, with shorter life span

Choosing the right foam is crucial for creating high-quality custom furniture. The type of foam impacts durability, aesthetics, and environmental sustainability.

Ensuring Sustainable and Safe Materials

Reputable manufacturers prioritize sustainable sourcing practices. They often use wood certified by organizations that promote responsible forest management.

Safety is paramount in custom furniture production. High-quality pieces are SGS Zero Formaldehyde Emission Certified, ensuring minimal Volatile Organic Compounds (VOCs). This certification guarantees low formaldehyde emissions, promoting healthier indoor air quality.

Manufacturers may employ specialized treatments to further reduce VOCs. These processes enhance the safety of the finished product without compromising its quality or appearance.

The Crafting Process from Concept to Completion

Custom furniture creation involves a meticulous journey from initial idea to finished piece. Skilled artisans combine design expertise with precise manufacturing techniques to bring unique visions to life.

Initial Design and Free Consultation

The process begins with a complimentary consultation. Clients share their ideas, preferences, and space requirements with expert designers. These professionals sketch initial concepts, considering factors like room dimensions and existing decor.

Designers present material options, including foam density, comfort level & fabric selection based on customer's preferences. They discuss functional needs such as seat depth, storages or any ergonomic features. Shop drawings will help clients visualize the final product.

Once the design is approved, the team creates detailed technical drawings. These blueprints guide the manufacturing process, ensuring accuracy in dimensions and specifications.

Expert Crafting Techniques

Skilled craftsmen take over in the workshop. They select premium materials, often locally sourced woods & foam & fabric lining, to match the approved design. Precision cutting and shaping begin, using both traditional and modern tools.

Artisans employ time-honored foam cutting method to craft out the shape yet do not missed out comfort level. CNC machines may assist with intricate details or repetitive tasks.

Each component is carefully crafted and test-fitted. Seat cushion, back cushions, and legs are adjusted for comfort seat height & depth. Craftsmen pay close attention to loose cushions & fabric joining details, ensuring aesthetic consistency across the piece.

Acquiring Your Custom Furniture

Ordering bespoke furniture involves a streamlined process with customization options and efficient timelines. Customers can expect personalized service and quick delivery for their unique statement pieces.

Placing Orders and Customization Options

Custom furniture orders begin with a free consultation. Clients discuss their vision with expert designers, exploring material choices like wood types and finishes. The design team creates detailed sketches and 3D renderings for approval. Customization extends to dimensions, colors, and functional features.

Customers can select:

- Foam Density

- Type of Sofa legs

- Custom upholstery fabrics

- Unique hardware finishes

- Built-in storage solutions

Orders are finalized once all details are confirmed. A deposit secures the production slot, ensuring timely manufacturing.

Timeline and Quick Delivery Expectations

The production timeline varies based on the complexity of the piece. Simple items like sofa may take 4-6 weeks, while intricate bedroom sets can require 6-8 weeks. Manufacturers prioritize efficiency without compromising quality.

Quick delivery options:

- Rush orders (additional fee)

- In-stock customizable pieces

- Modular designs for faster assembly

Clients receive regular updates on their order status. The delivery team schedules installation at the customer's convenience, ensuring a smooth setup of the new statement piece in its intended space.

Frequently Asked Questions

Custom furniture design involves important considerations around materials, processes, and care. Key factors include selecting appropriate woods, understanding finishes, and planning for manufacturing timelines.

How do I choose the right material for my custom-made furniture?

Consider the furniture's intended use and location. Durable fabrics like Aquaclean & Fabricut offer durability for high-traffic areas. Designer fabrics such as Clarke & Clarke , Osborne & Little suits well for decorative pieces. Factor in floral patterns and natural coloration to match your aesthetic preferences.

What are the steps involved in the furniture design process?

The process typically starts with a consultation to discuss ideas and requirements. Designers then create sketches or 3D renderings for approval. Once finalized, detailed technical drawings guide the manufacturing. A prototype may be built for complex designs before full production begins.

How long does it typically take to manufacture custom furniture in Singapore?

Timelines vary based on complexity and current workload. Simple pieces might take 4-6 weeks. More intricate designs could require 8-12 weeks or longer. Discuss specific timeframes with your chosen manufacturer, as they can provide more accurate estimates for your project.